Why Kraft Boxes Fail & How Soton Disposable Kraft Box Succeeds

The sight of grease seeping through a bag or staining a tabletop after takeout is a frustratingly common experience that points directly to limitations in standard packaging. Conventional disposable kraft box designs often struggle against the unique challenge posed by oils and fats. The issue isn't just about paper thickness; it's rooted in physics and chemistry. Kraft paper fibers naturally create capillary channels. Oils, possessing low surface tension, readily infiltrate these pathways, unlike water which might initially resist. Heat acts as an accelerator, making oils more fluid and invasive while simultaneously compromising the integrity of adhesives at critical seams and folds. During transit, movement creates hydraulic pressure, forcing liquids against container walls and into micro-gaps. Sauces containing emulsifiers or acids further complicate matters, potentially interacting with paper coatings. The result is a disposable kraft box that can appear intact externally while suffering internal failures leading to leaks.

Achieving consistent leak resistance requires a multi-faceted approach focused on material integrity and intelligent construction. It starts with selecting kraft paper not just for sustainability credentials, but for its inherent density and fiber structure – longer, tighter fibers create fewer invasion routes. The next layer involves advanced barrier technology. Effective solutions utilize plant-derived or mineral-based coatings specifically engineered to repel fats and oils. Crucially, these coatings must be applied with precision and consistency, ensuring complete coverage especially at high-stress points like folded edges and glued joints. Manufacturing precision is paramount. Seams must be bonded with heat-stable, food-safe adhesives applied cleanly to avoid weak spots. Corner designs benefit from reinforcement, and the overall container geometry should minimize flat surfaces where liquids pool against vulnerable walls. Testing under real-world conditions – prolonged hot oil exposure, vibration simulations, compression tests – is essential to validate performance before reaching customers.

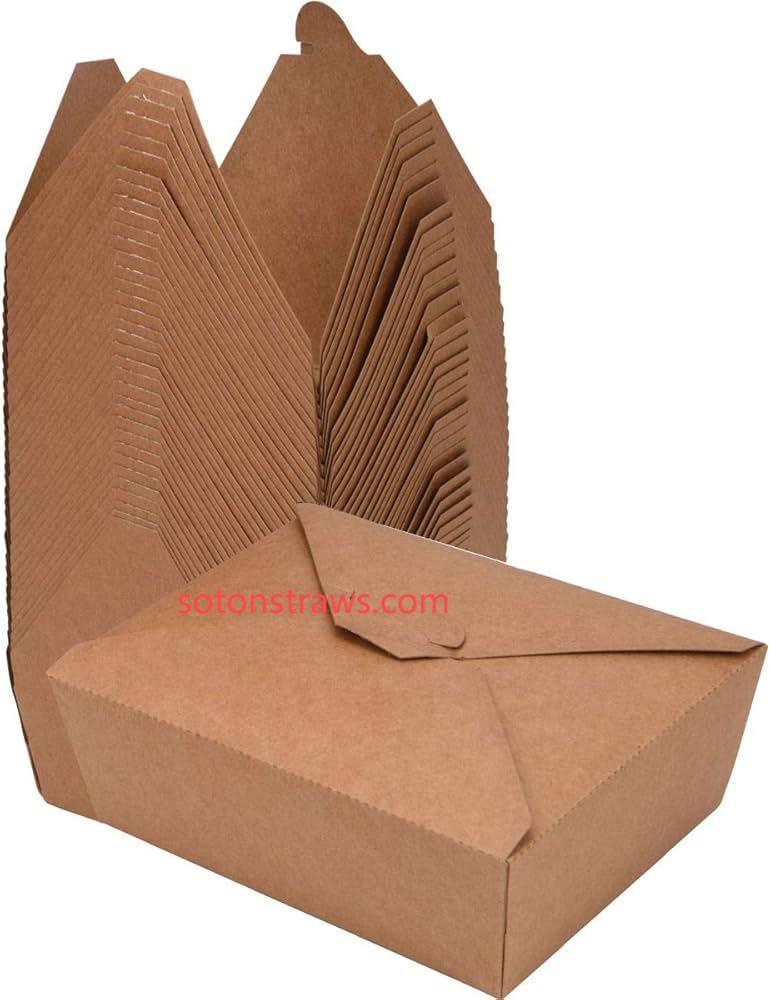

Tired of compromised meals and customer complaints? Soton delivers the solution. Our disposable kraft box line leverages CoreGuard technology. We combine ultra-dense, ethically sourced kraft with precision-engineered bio-barriers and reinforced construction to create containers that stand firm against the toughest greasy foods. Protect your brand reputation and delight customers with mess-free, eco-conscious takeout. Choose Soton – where performance meets sustainability.Click https://www.sotonstraws.com/product/ to reading more information.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Játék

- Gardening

- Health

- Otthon

- Literature

- Music

- Networking

- Más

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness