The Data Center in a Box: A Primer on the Modular Data Center

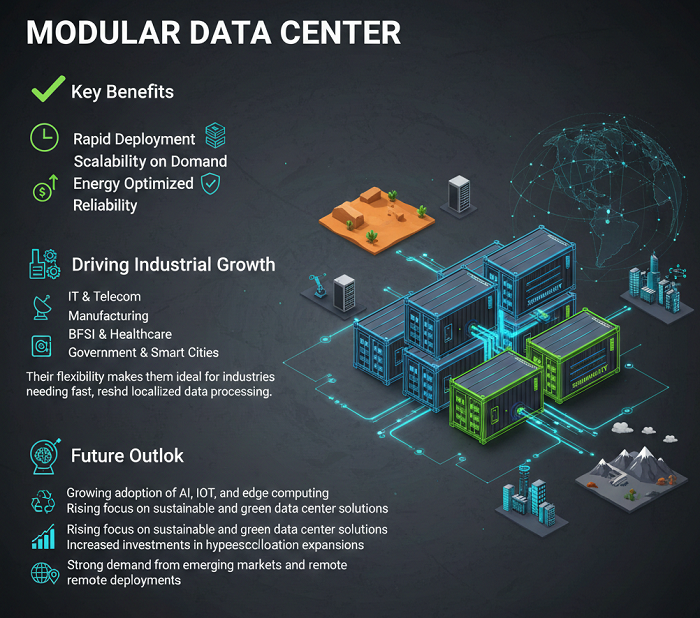

In the fast-paced world of digital infrastructure, the traditional method of building a data center—a slow, capital-intensive construction project—is being challenged by the agile and efficient Modular Data Center. This innovative approach involves pre-engineering, fabricating, and testing data center infrastructure components in a factory environment before shipping them to the desired location for final assembly. These components, or modules, can contain everything from IT racks and servers to power distribution units (PDUs), cooling systems, and physical security. Instead of building from the ground up on-site, a modular data center is assembled like a set of industrial-grade building blocks. This methodology fundamentally changes the economics and timelines of data center deployment, offering a faster, more predictable, and scalable solution to meet the ever-growing demand for computing capacity with unprecedented speed and flexibility.

The modular approach comes in two primary forms. The first is the all-in-one containerized data center, where all necessary IT and facility infrastructure is integrated into a standard ISO shipping container. These self-contained units are highly portable and can be deployed rapidly in almost any location with access to power and network connectivity, making them ideal for disaster recovery, temporary capacity expansion, or for bringing compute closer to remote industrial or military sites. The second form involves prefabricated modular components that are assembled on-site to create a larger, permanent data center facility. This could include individual modules for IT, power, and cooling that are brought together to form a complete building, offering the quality of a traditional data center but with the speed and predictability of factory-based construction.

The benefits of adopting a modular data center are numerous and compelling. The most significant advantage is speed of deployment. Because the modules are constructed and tested in parallel in a controlled factory setting while site preparation is underway, the total deployment time can be reduced by 30-50% compared to traditional construction methods. This allows businesses to respond much more quickly to new capacity demands. Another key benefit is scalability. Organizations can start with a smaller initial deployment and then incrementally add new modules as their computing needs grow. This "pay-as-you-grow" model avoids the massive upfront capital expenditure of over-provisioning a large traditional data center, leading to a much more efficient use of capital and a better total cost of ownership (TCO).

Furthermore, modular data centers offer greater predictability and quality. The factory-based manufacturing process allows for standardized designs, streamlined assembly lines, and rigorous quality control, which results in a more reliable and consistent end product than what can often be achieved with on-site construction, which is subject to weather delays and variable labor quality. The standardized and energy-efficient designs of many modular systems can also lead to a lower Power Usage Effectiveness (PUE) ratio, meaning they are more energy-efficient and have a smaller environmental footprint. This combination of speed, scalability, predictability, and efficiency makes the modular data center a powerful strategic tool for any organization needing to deploy IT infrastructure in a dynamic and fast-moving digital world.

Explore More Like This in Our Regional Reports:

South America CRM Software Market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness