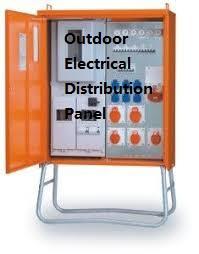

Nante Outdoor Electrical Distribution Panel: Modular Service Hub

In distributed power installations, selecting the correct Outdoor Electrical Distribution Panel early in the design phase prevents many downstream problems, since the Outdoor Electrical Distribution Panel must balance sealing, thermal management, and serviceability within a compact footprint. A thoughtfully specified outdoor panel protects circuits, streamlines maintenance, and reduces lifecycle cost — turning a vulnerable node into a predictable asset on any site.

Site Assessment: Match Panel To Environment

Begin by cataloging environmental stressors: precipitation intensity, freeze–thaw cycles, UV exposure, airborne particulates, and proximity to corrosive atmospheres such as coastal salt spray or chemical plumes. These factors determine IP and IK targets, material choices, and fastener treatments. Accurate site assessment avoids underspecifying the panel — a common cause of premature seal failure and increased field interventions.

Materials, Coatings, and Structural Design

Material selection is a primary durability lever. Powder-coated steel offers strength and economical performance when pretreatment and high-quality finishing systems are used. Stainless steel suits highly corrosive sites but carries a cost premium. GRP (glass-reinforced polyester) delivers electrical isolation and corrosion immunity while remaining lightweight. Pay attention to hinge, latch, and fastener metallurgy — marine-grade or passivated finishes reduce galvanic reactions and extend service life.

Internal Layout, Thermal Control, and Protective Devices

Thoughtful internal architecture separates heat-generating equipment from sensitive controls. Compartmentalized layouts, DIN-rail positioning, and removable mounting plates simplify installations and future upgrades. Integrate surge protection devices, circuit breakers, and appropriately rated isolators to limit fault propagation. For battery or inverter loads, include thermostatically controlled vents or low-power heaters to avoid condensation and maintain reliable operation across seasons.

Installation Best Practices And Accessibility

Design panels to reduce installation time: pre-marked gasket flanges, removable gland plates, captive screws, and generous cable-entry chambers all cut field labor. Ensure door swing clears cable harnesses and that internal wiring routes maintain proper bend radii to prevent insulation stress. Lockable handles and tamper-evident fasteners add site security while clear, durable labeling speeds commissioning and safe troubleshooting.

Compatibility And Brand Integration: Schneider And Others

Standardizing panel footprints and module spacing reduces supply-chain complexity. Panels that accept common modular components and match major manufacturer cutouts — for example, Schneider accessories and protective devices — simplify spares management and retrofit work. Compatibility reduces rework and helps teams replace components quickly during scheduled maintenance windows.

Maintenance Strategies That Reduce Failures

Preventive maintenance extends panel life: inspect gasket compression, torque-check terminal connections, and replace brittle seals before leakage begins. Keep a small stock of replaceable parts — gaskets, gland plates, and terminal blocks — to minimize outage durations. Routine thermographic scans reveal hot spots early, helping planners replace aging breakers or tighten loose connections before faults occur.

Monitoring And Smart Integration

Add modest telemetry — temperature, humidity, and door-open sensors — to enable condition-based maintenance. Low-power sensors in sealed pockets preserve enclosure integrity while enabling remote alarms that reduce emergency callouts. When designing for telemetry, provide serviceable access so sensors can be replaced or upgraded without compromising main seals.

Sustainability And Lifecycle Considerations

Design for disassembly: use standard fasteners, modular interiors, and separable coatings so individual components can be recycled or replaced. Prioritize replaceable wear items over one-piece replacements to limit waste. Lifecycle cost modeling often shows that slightly higher upfront investment in durable materials and modularity returns value over the panel’s operating life.

In practice, an outdoor electrical distribution panel that aligns materials, sealing strategy, thermal control, and accessibility to the actual site conditions becomes a predictable, long-lived element of infrastructure. Nante provides configurable options, test documentation, and service-support guidance to help specifiers match panels to applications. For full technical information, detailed specifications, and installation guidance, visit https://www.nante.com/news/industry-news/outdoor-electrical-distribution-panel-nante.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness