Revolutionizing Materials: Shanghai MSD's PVC Inflatable Fabric

In today’s manufacturing and material science industries, the integration of high-performance composites with innovative coating technologies has revolutionized the design and functionality of numerous products. One such material that has garnered significant attention is PVC Inflatable Fabric, which, when combined with advanced composite and coating technologies, creates a more durable, flexible, and efficient material for a variety of applications. This unique combination of materials is not only pushing the boundaries of traditional fabrics but is also offering new opportunities in industries such as boating, inflatable structures, and outdoor gear.

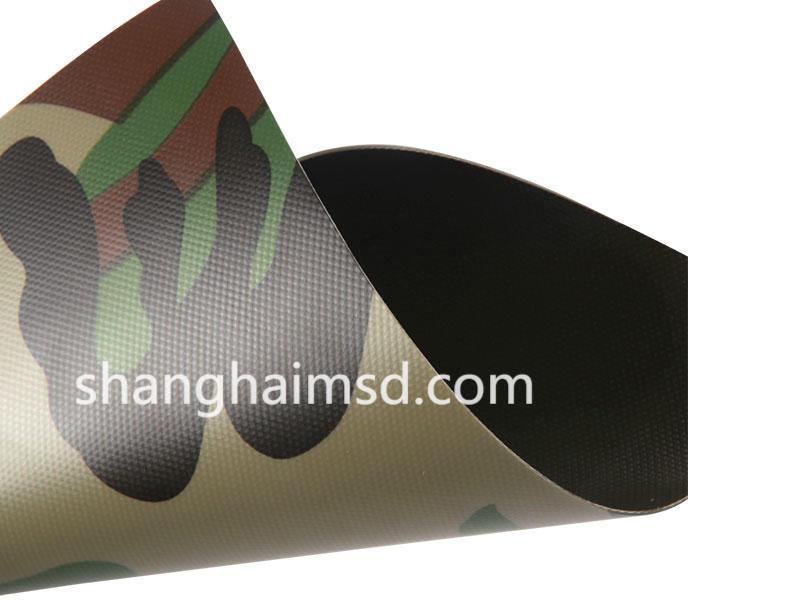

The inflatable fabric made from PVC is widely known for its flexibility, light weight, and ability to withstand various environmental stresses. It is often used in applications where both durability and flexibility are critical. However, what makes this textile even more remarkable is its ability to be enhanced by incorporating high-performance composite materials and innovative coatings. These enhancements allow manufacturers to address some of the inherent limitations of traditional PVC textiles, making them more resistant to wear, UV radiation, and harsh environmental conditions.

One of the most significant benefits of incorporating high-performance composites into PVC-based fabrics is the improvement in mechanical strength. By adding composite materials such as fiberglass or carbon fiber into the PVC structure, manufacturers can significantly enhance the textile’s tensile strength, abrasion resistance, and overall durability. This is especially important for applications like inflatable boats, where the material needs to withstand constant exposure to water, UV rays, and physical wear. The increased strength ensures that the material remains intact and functional over a longer period, even under challenging conditions.

Furthermore, high-performance composites also improve the thermal stability of PVC-based fabrics. PVC is known to become brittle in extreme temperature conditions, but when reinforced with composite materials, the textile’s ability to maintain its flexibility and strength across a broader temperature range is significantly improved. This is particularly important in outdoor applications, where the fabric is often exposed to varying temperatures, from the intense heat of the sun to the cold of early mornings and evenings. The combination of PVC with composite materials ensures that the fabric retains its structural integrity no matter the environmental conditions.

Innovative coatings play a crucial role in enhancing the performance of PVC Inflatable Fabric, offering additional protection and increasing its lifespan. Coating technologies, such as polyurethane (PU) or silicone coatings, can be applied to the material to enhance water resistance, UV protection, and abrasion resistance. For example, when used in inflatable boats or water sports equipment, these coatings prevent water penetration, reducing the risk of leaks and extending the product’s longevity. The added UV protection helps the fabric resist degradation caused by prolonged sun exposure, which is a common issue in outdoor applications. These coatings also reduce the likelihood of the material becoming discolored or weakened by environmental factors, keeping the fabric looking and performing like new for a longer period.

Additionally, the use of advanced coatings can significantly improve the fire resistance and chemical resistance of PVC-based fabrics. In industrial settings, where materials may be exposed to hazardous chemicals or high temperatures, the incorporation of fire-retardant coatings can be a game changer. This added protection ensures that the fabric remains safe and functional, even in environments where other materials might fail. The versatility of these coatings allows manufacturers to customize the properties of the PVC textile, tailoring it to specific industry needs and ensuring that it meets the highest standards of safety and performance.

For companies like Shanghai MSD International Trading Co., Ltd., the combination of PVC Inflatable Fabric with high-performance composites and coatings presents a unique opportunity to deliver superior materials to customers across various industries. Shanghai MSD has been at the forefront of incorporating these advanced materials into their product offerings, ensuring that their inflatable products and applications meet the rigorous demands of modern use. As the demand for more durable, lightweight, and high-performance materials continues to grow, the integration of high-performance composites and innovative coatings in PVC fabrics will remain a driving force in material science.

In conclusion, the marriage of PVC Inflatable Fabric with high-performance composites and cutting-edge coatings is setting new standards in material performance. Whether for inflatable boats, outdoor equipment, or industrial applications, this combination of materials ensures superior strength, durability, and long-lasting functionality. Shanghai MSD International Trading Co., Ltd. continues to lead the way in offering top-quality, enhanced PVC fabric that meets the diverse needs of industries worldwide.For more information on PVC Inflatable Fabric and its applications in inflatable boats and other industries, visit https://www.shanghaimsd.com/news/industry-news/pvc-inflatable-boat-fabric-the-core-material-that-make-inflatable-boats-stronger.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness